Silnik krokowy 10BY mini 5V o średnicy 10 mm, mikro silnik krokowy PM

Opis

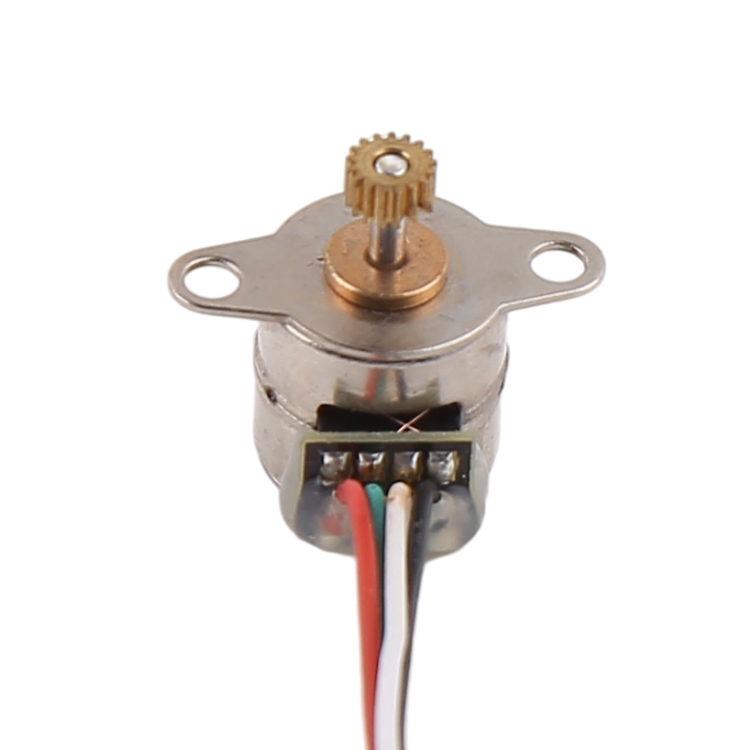

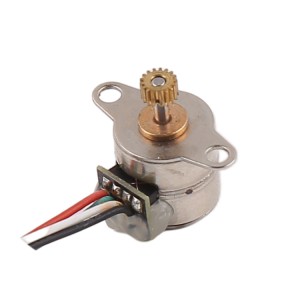

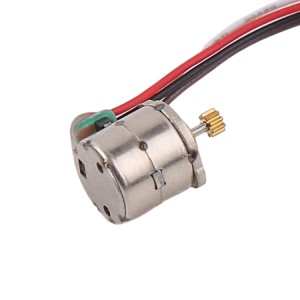

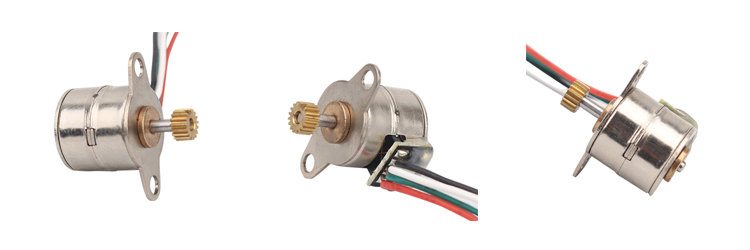

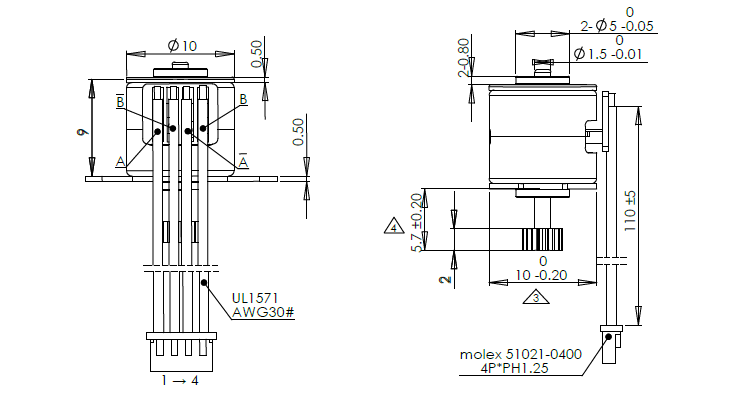

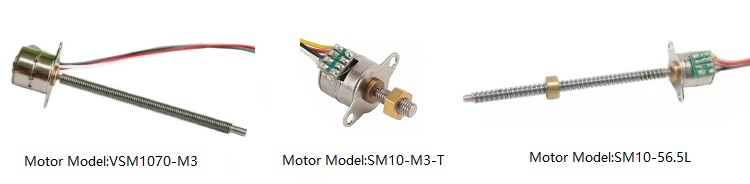

VSM1070 to miniaturowy, wysokiej jakości, cichy silnik krokowy. Średnica silnika wynosi 10 mm, wysokość silnika 10 mm, rozstaw otworów montażowych w uchu silnika 14 mm, a wysokość wału wyjściowego 5,7 mm. Wysokość wału wyjściowego silnika można dostosować do potrzeb instalacyjnych klienta. Konwencjonalny wał wyjściowy silnika jest wyposażony w miedziane koła zębate (moduł przekładni 0,2, liczba zębów 17, grubość koła zębatego 2 mm). Koła zębate można również dostosować do potrzeb instalacyjnych klienta.

Tryb połączenia silnika to przewód łączący lub goła igła, FPC itp. można dostosować

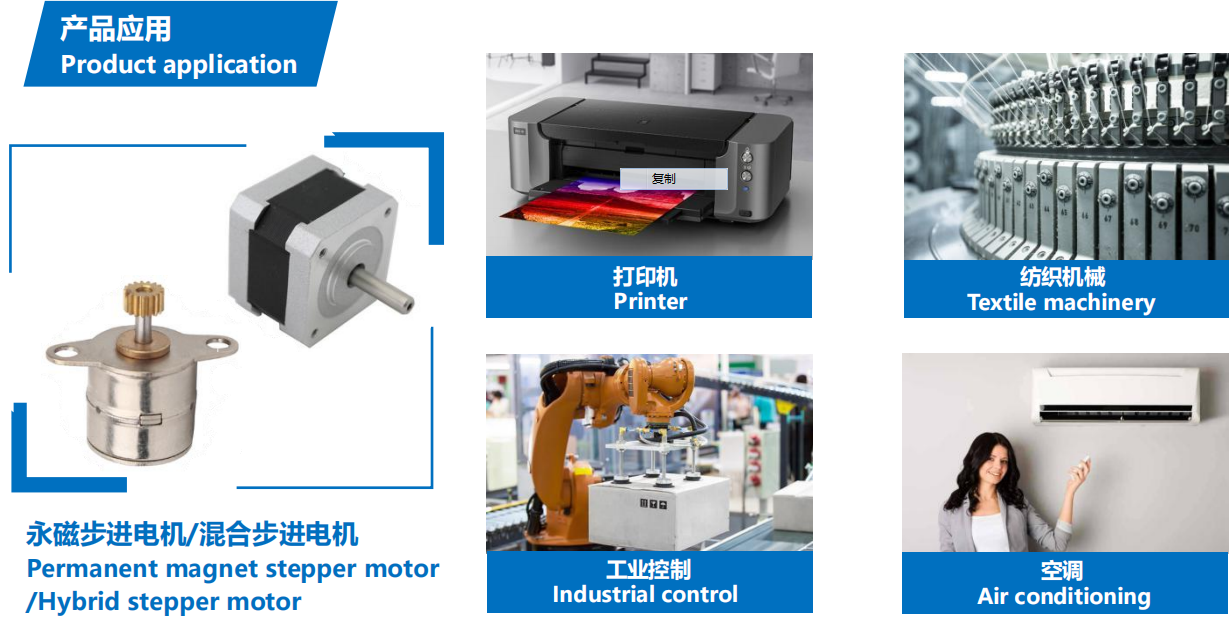

Ze względu na niewielkie rozmiary, wysoką precyzję, łatwą kontrolę i inne doskonałe cechy, ten mikrosilnik krokowy jest szeroko stosowany w aparatach fotograficznych, instrumentach optycznych, obiektywach, precyzyjnych urządzeniach medycznych i innych dziedzinach.

Parametry

| NAZWA PRODUKTU | SILNIK KROKOWY 10MM |

| MODEL | VSM1070 |

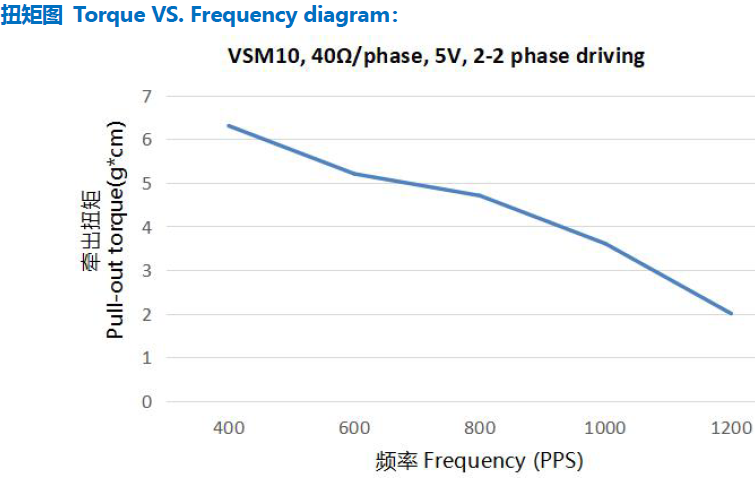

| MAKSYMALNA CZĘSTOTLIWOŚĆ ROZPOCZĘCIA | 800 PPS min. (przy 5,0 V prądu stałego) |

| MAKSYMALNA CZĘSTOTLIWOŚĆ OBROTÓW | 1100 PPS min. (przy napięciu 5,0 V DC) |

| MOMENT DOCIĄGANIA | 5,4 gf-cm min. (przy 500 PPS, 5,0 V DC) |

| MOMENT WYCIĄGANIA | 6,0 gf-cm min. (przy 500 PPS, 5,0 V DC) |

| KLASA IZOLACJI | KLASA E DLA CEWEK |

| WYTRZYMAŁOŚĆ IZOLACJI | 100 V AC PRZEZ JEDNĄ SEKUNDĘ |

| REZYSTANCJA IZOLACJI | 1 MΩ (prąd stały 100 V) |

| ZAKRES TEMPERATURY PRACY | -10 ~+60 ℃ |

| USŁUGI OEM I ODM | DOSTĘPNY |

Rysunek projektowy

Przykład tego samego typu

O schemacie momentu obrotowego miniaturowego silnika krokowego

ZastosowanieO mikrosilniku krokowym

Nasze mikrosilniki krokowe mają zazwyczaj kąt kroku 18 stopni (pełny krok).

Oznacza to, że wykonanie jednego obrotu wymaga wykonania 20 kroków.

Kąt kroku silnika jest związany z konstrukcją wewnętrznego stojana.

Mamy mikrosilniki krokowe o różnych średnicach, a moment obrotowy silnika zależy od jego rozmiaru.

Oto zależność pomiędzy średnicą silnika i momentem obrotowym (przy odpowiedniej częstotliwości pracy i napięciu znamionowym):

Silnik 6 mm: około 1 g*cm

Silnik 8 mm: około 3 g*cm

Silnik 10 mm: około 5 g*cm

Silnik 15 mm: około 15 g*cm

Silnik 20 mm: około 40 g*cm

Aplikacja

Prędkość silnika zależy od częstotliwości napędu i nie ma nic wspólnego z obciążeniem (chyba że silnik traci kroki).

Dzięki precyzyjnej regulacji prędkości silników krokowych, sterowanie krokowe za pomocą sterownika pozwala na uzyskanie precyzyjnego pozycjonowania i kontroli prędkości. Z tego powodu silniki krokowe są preferowanym wyborem w wielu zastosowaniach precyzyjnego sterowania ruchem.

Usługa personalizacji

Konstrukcja silnika może być dostosowana do wymagań klienta, w tym:

Średnica silnika: mamy silniki o średnicy 6 mm, 8 mm, 10 mm, 15 mm i 20 mm

Rezystancja cewki/napięcie znamionowe: rezystancję cewki można regulować. Im wyższa rezystancja, tym wyższe jest napięcie znamionowe silnika.

Konstrukcja wspornika/długość śruby pociągowej: jeśli klient chce, aby wspornik był dłuższy/krótszy, ze specjalną konstrukcją, taką jak otwory montażowe, można ją regulować.

PCB + kable + złącze: konstrukcja PCB, długość kabla i rozstaw złączy są regulowane; na życzenie klienta można je wymienić na FPC.

Informacje o czasie realizacji i pakowaniu

Czas realizacji próbek:

Silniki standardowe dostępne w magazynie: w ciągu 3 dni

Silniki standardowe niedostępne w magazynie: w ciągu 15 dni

Produkty dostosowane do indywidualnych potrzeb: około 25–30 dni (w zależności od stopnia skomplikowania dostosowania)

Czas realizacji budowy nowej formy: zazwyczaj około 45 dni

Czas realizacji produkcji masowej: zależny od wielkości zamówienia

Opakowanie:

Próbki pakowane są w gąbkę piankową i papierowe pudełko, wysyłane ekspresowo

Produkcja masowa, silniki pakowane są w tekturowe kartony z zewnętrzną przezroczystą folią. (wysyłka drogą lotniczą)

W przypadku wysyłki drogą morską produkt będzie pakowany na paletach

Metoda wysyłki

W przypadku próbek i przesyłek lotniczych korzystamy z firm FedEx/TNT/UPS/DHL.(5~12 dni w przypadku usługi ekspresowej)

W przypadku transportu morskiego korzystamy z usług naszego agenta żeglugowego i wysyłamy przesyłki z portu w Szanghaju.(45~70 dni na wysyłkę morską)

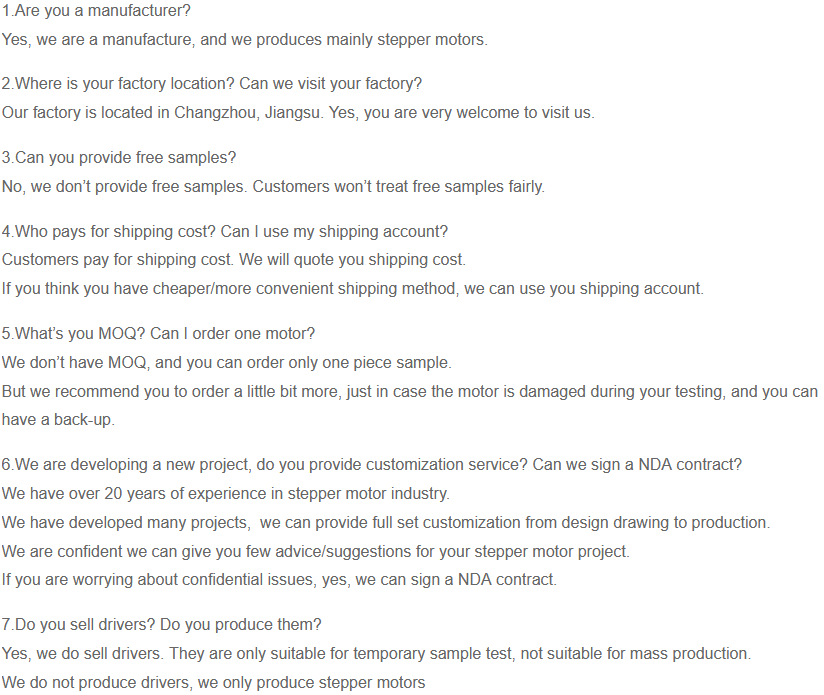

Często zadawane pytania

Często zadawane pytania

1. Silnik krokowy i przekładnia redukcyjna:

Silnik krokowy wyposażony w przekładnię redukcyjną używany razem, duża prędkość wyjściowa silnika krokowego, mała prędkość momentu obrotowego, podłączony do przekładni redukcyjnej, wewnętrzny zestaw kół redukcyjnych przekładni utworzony przez przełożenie redukujące, duża prędkość wyjściowa silnika krokowego zmniejszona, ale także w celu zwiększenia momentu obrotowego przekładni, aby uzyskać idealny efekt przekładni; efekt redukcji zależy od przełożenia przekładni, im większe przełożenie, tym mniejsza prędkość wyjściowa i odwrotnie.

2.Jak wykorzystać krzywą wykładniczą do sterowania prędkością silnika krokowego?

Krzywa wykładnicza, w programowaniu, najpierw oblicza stałe czasowe przechowywane w pamięci komputera, a następnie wskazuje na wybór. Zazwyczaj czas przyspieszania i hamowania silnika krokowego wynosi 300 ms lub więcej. Zbyt krótki czas przyspieszania i hamowania, w przypadku zdecydowanej większości silników krokowych, utrudni osiągnięcie wysokiej prędkości obrotowej.

3. Rozsądny zakres generowania ciepła przez silnik krokowy:

Zakres dopuszczalnego nagrzewania silnika zależy w dużej mierze od poziomu izolacji wewnętrznej silnika. Izolacja wewnętrzna ulegnie zniszczeniu dopiero w wysokich temperaturach (powyżej 130 stopni). Tak więc, dopóki temperatura wewnętrzna nie przekroczy 130 stopni, silnik nie uszkodzi pierścienia, a temperatura powierzchni będzie w tym punkcie poniżej 90 stopni. Dlatego temperatura powierzchni silnika krokowego w zakresie 70-80 stopni jest normalna. Prosta metoda pomiaru temperatury, przydatny termometr punktowy, pozwala również w przybliżeniu określić: ręką można dotknąć dłużej niż 1-2 sekundy, nie więcej niż 60 stopni; ręką można dotknąć tylko około 70-80 stopni; kilka kropli wody szybko odparowuje, jest powyżej 90 stopni.